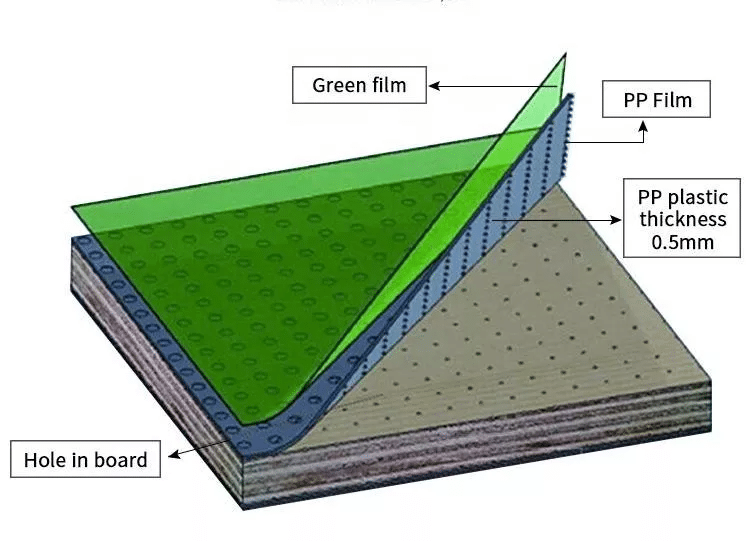

With sustainability becoming a key focus in the global construction industry, Polypropylene Film Coated Plywood is emerging as a new-generation product that combines strength, durability, and environmental benefits. This innovative panel is manufactured by coating both sides of the plywood core with a 0.5mm thick polypropylene (PP) plastic film, which is highly resistant to wear and corrosion. By tightly bonding the PP film with the inner plywood core, the product achieves physical and mechanical properties that are significantly superior to traditional film faced plywood.

Compared with conventional options, polypropylene film coated plywood offers higher reusability, improved resistance to moisture, and greater surface durability. Its smooth PP finish ensures excellent concrete casting performance with fewer defects, reducing the need for additional plastering work and helping contractors save both time and cost on construction projects.

This product is now widely applied in high-rise buildings, bridges, tunnels, and infrastructure projects. With rising raw material costs and stricter global environmental regulations, many contractors and developers are choosing polypropylene film coated plywood as a practical and eco-friendly alternative. Experts predict that its adoption will expand rapidly in the coming years, shaping a greener and more efficient future for the construction industry.

Advantages of Green PP Film Faced Plywood

Durable Surface Layer

The 0.5mm PP film coating provides exceptional protection against water, scratches, and wear. This surface ensures the panels maintain performance and appearance even under frequent use in demanding conditions.

Superior Strength and Stability

Constructed with quality wood cores such as poplar, eucalyptus, combi core, or birch, the panel delivers excellent load-bearing capacity. Its structure is designed to minimize warping or bending, ensuring long-lasting stability.

Moisture Resistance

Edges are sealed with waterproof paint to provide extra protection, preventing swelling and delamination in humid or wet environments.

High Load-Bearing Performance

Engineered for heavy-duty applications, the panel performs reliably in concrete formwork, flooring, and scaffolding, supporting significant weight without structural compromise.

Reusable and Cost-Effective

The combination of a durable PP surface and a stable plywood core allows for multiple reuse cycles. This reduces replacement frequency, lowers project costs, and contributes to sustainable construction practices.